Injection molding is a critical process in the manufacturing industry, used to create a wide range of plastic products. However, the traditional injection mold process can be time-consuming and expensive, especially for complex designs. That's why we're excited to announce a new injection mold technology that promises to revolutionize the industry.

The new technology, called "rapid tooling," uses 3D printing to create injection molds much faster and more cost-effectively than traditional methods. With rapid tooling, a 3D model of the mold is printed, and then the mold is produced using standard injection molding processes. This results in a much shorter lead time, as well as a significant reduction in production costs.

One of the key advantages of rapid tooling is that it allows for the creation of complex injection molds that would be difficult or impossible to produce using traditional methods. This means that manufacturers can now create more intricate designs with ease, which opens up new possibilities for product innovation and customization.

In addition to the benefits for manufacturers, rapid tooling is also good news for consumers. With reduced production costs, manufacturers can now offer their products at lower prices, making them more accessible to a wider audience.

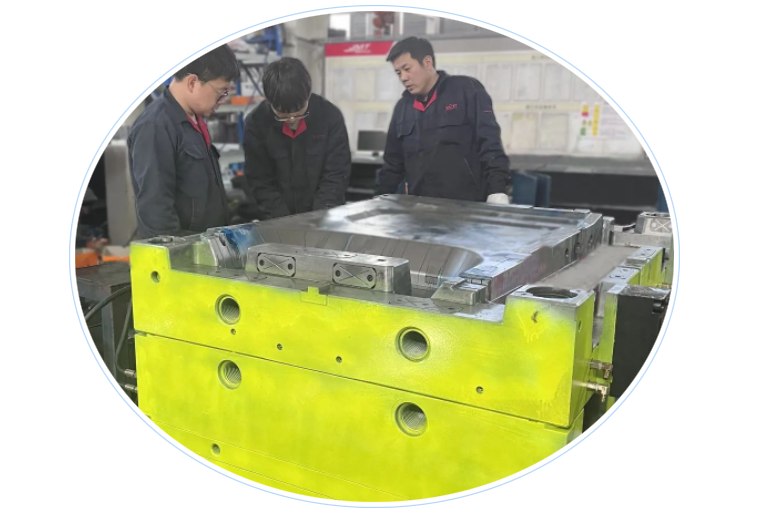

At JMT, we're proud to be at the forefront of this exciting new technology. We're already using rapid tooling to create injection molds for a range of products, from automotive components to consumer goods. Such as Automotive injection mold, Children's products injection mold, Home appliance injection mold, SMC & BMC & GMT compression mold, Household & Industrial injection mold. Our customers have been thrilled with the results, and we're confident that rapid tooling will continue to revolutionize the injection mold industry in the years to come.

JMT Mould Co., Ltd. is located in Huangyan, Taizhou, Zhejiang Province, China. Founded in 2005, covering an area of 23,000 square meters, JMT is a large innovative mould manufacturing enterprise specilized in design, manufacturer Automoive Mould, Household Products Mould, Home Appliance Mould, and SMC Mould etc. JMT owns world's first-class mold processing equipment, five axis high-speed machining center, Taiwan high-speed milling machining center, high precision double-head EDM and other 50 CNC processing equipment, more than 10 Haitian injection molding machines, CMM, material hardness detection, flaw detector and other equipments. JMT keeps improving with advanced concept, with senior R&D and design team, experienced bench workers and professional management team, using scientific and rigorous management system and advanced processing equipment to ensure high quality.

JMT are committed to deliver a world class service and adopt the principles of continuous improvement, providing our customer one-stop moulding solutions!